Development of Rudder Pedals with Integrated Brake Control

We are currently developing a modular pedal system for rudder control with integrated independent braking for the left and right main wheels. The goal is to provide a precise, ergonomic, and reliable solution for ultralight and experimental aircraft.

The mechanical design allows for differential braking, improving ground handling—particularly during taxiing and tight turns. Key focus areas include lightweight but robust construction, play-free bearing systems, and defined return forces. The system is in an advanced stage of development and is currently undergoing intensive testing and optimization in functional prototypes.

D-EPDJ

In the year

2025

Product category

Engineering

Art der Arbeit

Technical research

Engineering Tailored rudder pedal system with integrated braking

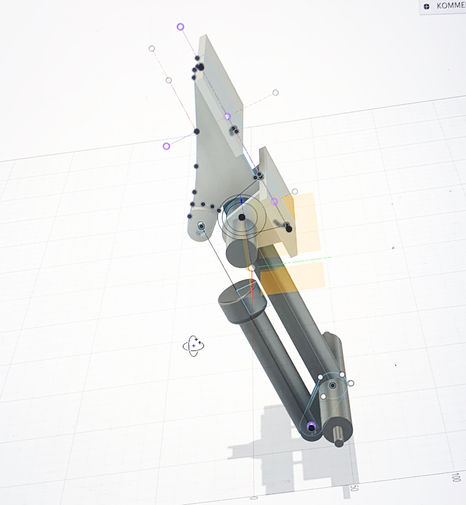

Custom Development: Rudder Pedals with Integrated Brake Function for a Pietenpol Air CamperOn behalf of a customer, I developed a custom rudder pedal system with integrated differential braking for the Pietenpol Air Camper. The original 1929 aircraft design does not include wheel brakes—only a simple U-shaped rudder bar for rudder input from the front seat.

The customer requested a modern solution that would enable effective braking without compromising the historical character of the aircraft. The development process began with initial technical concept sketches, focusing on functionality, mechanical durability, and seamless integration into the existing structure. The complete design was created using CAD software. Material selection was evaluated for suitability, and load simulations as well as FEM (Finite Element Method) analyses were performed to define safe load limits and ensure structural integrity.

Early on, 3D-printed prototypes were used to validate the fit and optimize the installation process. This allowed for real-world functional testing before final production. The system enables precise differential braking of the left and right main wheels, offering significantly improved ground handling—especially on grass runways or during tight maneuvering. The mechanical design meets high standards for strength, responsiveness, and play-free operation and is specifically adapted to the geometry of the Pietenpol.

This development builds on my years of experience with vintage aircraft, supported by in-depth research and direct exchange with Pietenpol builders and owners in the United States. Proven design principles were retained where appropriate and enhanced where necessary. The result is a reliable, lightweight, and field-ready pedal system that gives the customer enhanced control on the ground—without sacrificing the classic look and feel of the aircraft.

The prototype of the pedal was manufactured using 3D printing and designed in such a way that all mechanical functions could be realistically tested. It was installed directly in the aircraft to verify the fit and, if necessary, make design adjustments.

This approach ensured that the system functioned flawlessly and integrated seamlessly into the existing structure before final production. Only after successful testing were the components precisely machined from the specified materials using CNC equipment.