We carry out tensile, flexural, and compressive strength tests to assess the mechanical properties of materials.

Bending strength

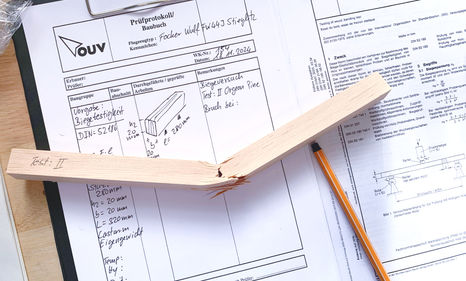

Bending strength – also referred to as flexural strength – is determined at our facility in accordance with DIN 52186. This standard describes a material’s resistance to fracture or deformation under bending load.

For wood species, bending strength is typically expressed in N/mm² (newtons per square millimeter). For the test procedure, we use standardized wood samples with a cross-section of 20 x 20 mm and a specimen length of 320 mm. The support span between the loading points is 280 mm.

Test specimens can be cut by us or provided by the customer as pre-prepared samples. In either case, a moisture content measurement using the Darr method must be conducted prior to testing – either performed in-house or verified through customer documentation. This ensures that the test results can be properly classified and evaluated in accordance with the applicable standard.

Biegeversuch an Holzproben

Tensile strength

The tensile strength of wood is determined at our facility in accordance with the specifications of

DIN EN 408. This standard covers the mechanical properties of solid wood and wood-based materials – particularly regarding their suitability as construction products, including the tensile strength of solid timber, glued laminated timber, and engineered wood products.

For testing, we use standardized specimens with a tensile length of 250 mm, a cross-sectional area of 70 mm², a width of 14 mm, and a height of 5 mm. Test specimens can either be cut directly by us or submitted by the customer as pre-prepared samples.

In all cases, a moisture content determination using the Darr method is carried out beforehand to ensure that the material values are correctly assigned and that the results can be evaluated in compliance with the standard.

This test is either conducted in-house or must be accompanied by appropriate documentation provided by the customer.

The proper clamping of a tensile test specimen in the grips is carried out in full compliance with the applicable standards and with the utmost care. This step requires time, as precise alignment is essential to ensure meaningful and reliable test results.

To guarantee reproducible results, we have developed our own tensile testing machine.

It is equipped with a high-precision load sensor that continuously records the applied forces and visualizes them in a diagram as an stress–strain curve. This allows the entire force progression up to material failure to be made visible – from the initial load to the actual break. The result is a meaningful, traceable test in accordance with current standards, documented with high accuracy.

Compressive strength

The compressive strength of wood is determined at our facility in accordance with DIN EN 408. This standard defines the procedure for assessing the mechanical properties of wood and wood-based materials – particularly under load applied parallel to the grain. For testing, we use standardized wood compression cubes with dimensions of 13 x 13 x 13 mm, corresponding to a cross-sectional area of 169 mm². The load is applied axially – i.e., parallel to the grain direction – under controlled compression conditions.

Test specimens can either be cut by us or submitted by the customer as pre-prepared samples. In all cases, a moisture content measurement using the Darr method must be carried out beforehand – either directly at our facility or documented by the customer. This ensures that the compressive strength is evaluated accurately and in full compliance with the standard.